From Manual Labor, to Mechanization, to AI-Assisted Smart Farming

The Internet of Things (IoT) is a network of smart devices that connect and share data over the internet.

Like most of the modern industrialized world, the agriculture industry is undergoing a much-anticipated shift toward maximizing efficiency, productivity, and sustainability. Driven by the need to address challenges such as labor shortages, rising operating costs, population growth, and climate change, decision-makers are increasingly inclined to embrace new technologies that mechanize or automate tasks. The degree to which manual labor is replaced depends on the adoption and integration of key technologies such as robotics, autonomous transporters, mechanized harvesters, and the integration of these components into an Internet of Things (IoT) system that makes predictions and decisions using artificial intelligence (AI) and machine learning (ML).

The first step in modernizing an agricultural operation is using mechanized equipment. Tractors are the main technology leading mechanized farming because they can be fitted with various attachments to perform multiple tasks. Hay balers can cut, bundle, and wrap hay in one pass. Plow tractors can till soil in preparation for planting while placing seeds quickly and precisely, and sprayer tractors can apply fertilizers, pesticides, and herbicides exactly where needed [1]. Once crops are ready for harvest, mechanized harvesting machines reduce harvesting time, minimize crop loss, and preserve crop quality. Depending on the crop, mechanized harvesters will operate by combing, cutting, pulling, snapping, twisting, stripping, shaking, and compacting various plant materials [2].

An Oxbo brand mechanized harvesting machine.

Mechanized harvesting can also be classified into three levels: low, intermediate, and advanced mechanization. Low mechanization involves hand-held tools that provide minimal mechanical assistance, such as a shake-and-catch harvester. Intermediate mechanization includes vibrating comb harvesters, trunk shakers, canopy shakers, and conveyors. Finally, advanced mechanization employs full automation for self-propelled machinery that combines smart sensors, AI, machine learning, and the Internet of Things [3].

Types of Mechanized Harvesters

An Oxbo brand mechanized berry harvesting machine.

The main types of mechanized harvesters include combine harvesters, root crop harvesters, forage harvesters, sugar crop harvesters, tree harvesters, grapevine harvesters, cotton harvesters, vegetable harvesters, and multi-function harvesters that combine harvesting capabilities with other agricultural functions.

Combine Harvesters

An Oxbo brand mechanized spraying machine.

Combine harvesters perform the tasks of reaping (cutting), threshing (separating grain from stalks), and winnowing (cleaning the grain and removing debris). These combines come in a variety of styles and levels of technology. Self-propelled combines have an onboard engine and can be fully automated or require an operator. Tractor-pulled combines require a driver to operate the tractor. Hillside combines come equipped with auto-levelling systems to work crops on sloped land, and rotary combines use rotating drums instead of the traditional threshing bars [4]. Emerging automation trends include GPS and auto-steering, yield mapping sensors to analyze yield, and AI decision-making concerning rotor speed, fan speed, and sieve settings.

Root Crop Harvesters

Root crop harvesters can be self-propelled or tractor-towed and are used to harvest produce that grows underground such as potatoes, carrots, beets, onions, and more.

An Oxbo brand harvesting machine harvesting potatoes from multiple rows simultaneously.

Smaller models work on a single row, while larger models can harvest from multiple rows simultaneously. They work by digging the soil to loosen the crop, removing debris, and depositing the cleaned crop into storage bins for later sorting [6]. New root crop harvesting machines are seeing automation technology such as depth control sensors, AI-controlled airflow soil separation, and real-time camera sorting to detect and remove damaged crops [7].

Forage Harvesters

Forage harvesters are used to harvest produce such as corn or grass by cutting crops into small pieces using blades and blowers. These harvesters can be self-propelled or tractor-mounted. New technology trends include moisture sensors that adjust cutting length and AI tracking of crop conditions [9].

Sugar Crop Harvesters

Sugar can be made from sugar beets or sugar cane. Sugar beet harvesters are able to lift the beets out of the ground using rotating filters while removing beet tops and excess soil [11]. Sugarcane harvesters cut stalks, remove leaves, clean the stalks, and chop the cane into small billets [12]. Since these crops can grow on uneven terrain and stalks are cut close to the ground, mechanized sugar crop harvesting machines can come equipped with auto-levelling technology to adjust blade height. Certain models also include AI cane sorting, which determines which stalks are ripe and ready to harvest [13].

Tree and Vine Harvesters

Tree and vine harvesting machinery is used to gather fruit, nuts, grapes, and other produce that may grow on a tree or vine. The main mode of operation for harvesting this produce involves some sort of shaking, vibration, or suction to loosen ripe produce.

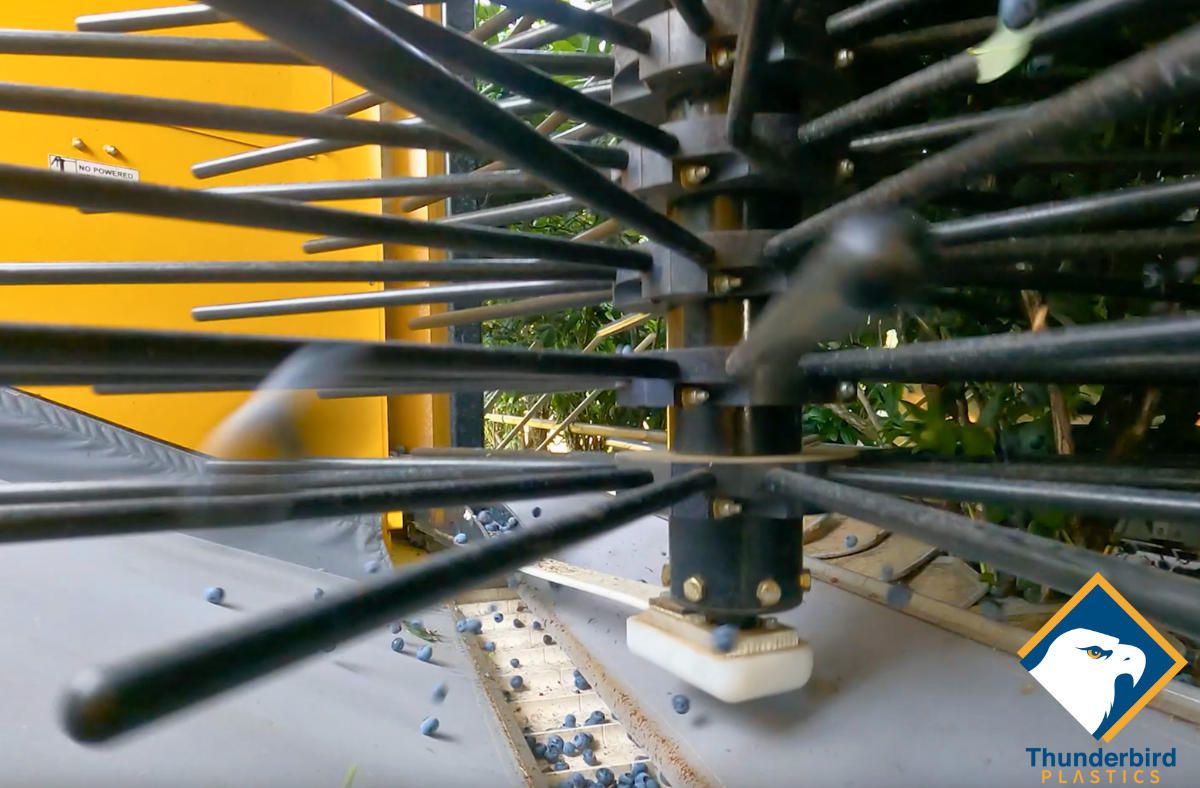

Pivotal striker bars are used to dislodge ripe berries from branches and vines.

Depending on the vine structure, some harvesting machines use a pivotal striker and bow-row to loosen delicate fruits and berries. Fruit is collected by fishplates onto conveyors and cleaned using hydraulic fans. Some multi-function units may be affixed with attachments that spray, trim, and prune [14]. Nut harvesters may shake trunks and catch falling nuts in an overhead frame, or sweep & pick up machines may sweep nuts into rows before vacuuming them up [15]. In the tree and vine harvesting sphere, automation trends include the use of robotics and AI-based optical systems to sort ripe fruit and cut undesired components out [16].

Cotton Harvesting Machines

Cotton harvesting machines come in two varieties: cotton pickers and cotton strippers. Cotton pickers use rotating spindles to pull cotton from bolls and leave the plant undamaged for future growth. This method yields softer, higher-quality cotton. Cotton stripping machines strip the entire plant of cotton, leaves, and all debris. This method is used in dry regions where cotton is less dense. Due to the gathering of unwanted debris, additional processing is required at the gin, a machine designed to separate cotton fibers from seeds and other debris [17]. Cotton harvesting machines are being automated with robotics, GPS guidance, and moisture sensors, which can adjust harvesting speed based on the quality of the fibers [18, 19].

Vegetable and Specialty Crop Harvesting Machines

An Oxbo brand leafy green harvesting machine.

Vegetables grow in a wide variety of ways. Depending on whether the vegetable is a leafy green grown above ground, a vegetable grown on a vine, or a bulb or root vegetable grown underground, harvesting technology will differ. These machines may use blades to cut, shake the plants or vines, or lift vegetables or bulbs from the soil. Sensors will be used to sort harvested produce, and fans and conveyors will be used to clean and transport produce into bins. Recent automation trends include the use of robotic arms equipped with AI-based vision technology to pick delicate crops like berries and tomatoes while leaving unripened produce on the vine [20].

Top Brands of Harvesting Machines by Category

Tree & Vine Harvesting Machines

Oxbo International – 8000 Series Grape Harvesters (multi-purpose vineyard machines with soft-catch technology for minimal fruit damage).

New Holland – Braud 9000 Series (dual head canopy shakers for gentle grape removal and efficient sorting).

Monchiero – Nut Harvesters (self-propelled vacuum-based collection for almonds, walnuts, and hazelnuts).

BEI – Tree Shakers (leading manufacturer of almond and walnut harvesters).

Combine Harvesters (Grain & Cereal Crops)

John Deere – S-Series & X-Series Combines (AI-powered automation and high-efficiency harvesting for large-scale farms).

Case IH – Axial-Flow Series (single-rotor technology for smooth and efficient grain separation).

New Holland – CR Revelation Series (Twin Rotor system for improved threshing and grain quality).

CLAAS – LEXION Series (high-speed, high-capacity combine harvesters with precision automation).

Fendt – IDEAL Series (high-performance combines with advanced AI integration).

Root Crop Harvesters (Potatoes, Carrots, Beets, etc.)

Grimme – Self-Propelled & Towed Potato Harvesters (adjustable depth control and minimal crop damage).

AVR – PUMA 4.0 (AI-assisted depth control for precision digging and soil separation).

Dewulf – RA Series (automated cleaning and sorting system for efficient root crop harvesting).

Forage Harvesting Machines (Silage & Hay Harvesters)

Krone – Big X Series (high-horsepower machines for large-scale silage production).

CLAAS – JAGUAR Series (precision cutting, automatic feed rate adjustment, and superior chop quality).

John Deere – 9000 Series (AI-based feed adjustment for optimized chopping efficiency).

Sugar Crop Harvesting Machines (Sugarcane & Sugar Beet)

John Deere – 3520 Series (real-time tracking of sugar yield with automated adjustments).

Case IH – A8000 Series (high-speed cutting technology and superior stalk handling).

Ropa – Tiger Series (AI-assisted sugar beet lifting and cleaning).

Cotton Harvesting Machines

John Deere – CP770 Series (automated module building for higher efficiency).

Case IH – Module Express (single-pass harvesting with integrated module-building technology).

Vegetable Harvesting Machines

Oxbo – Specialty Harvesters (designed for leafy greens, soft fruits, and high-value crops).

Pellenc – Tomato Harvesters (AI-driven sorting technology for improved efficiency).

Tong Engineering – Advanced Onion & Carrot Harvesters (automated depth control and soil separation).

Mechanization in Other Farming Sectors

Mechanization is seen in many other forms of farming, including aquaculture, oyster farming, mushroom farming, seaweed farming, and more. In oyster farming, harvesting can be mechanized, while some of the growth and later cleaning processes can be automated [22]. In fish farming, automated feeding systems are commonly used [23]. Seaweed farming also uses mechanized systems for harvesting and seeding [24]. Insect farming utilizes automation for feeding, harvesting, and waste management. Bee farms are increasingly adopting mechanized tools for hive management, and mushroom farming is using automated systems for managing and monitoring growing conditions. In all types of farming and cultivation industries, mechanization and automation lead to more sustainable farming practices.

Economic Findings: Manual Harvesting Costs vs. Mechanical Harvesting Costs

Mechanization in agriculture significantly reduces labor costs and increases harvesting and processing efficiency, leading to greater profitability for farmers. Lowered production costs get passed down to the end consumer, resulting in stabilized food prices. A 2017 study by Speradio et al. compared the costs of manual and mechanized production of olive oil. It was found that mechanizing the harvesting process can save up to 90% of labor costs and reduce production costs of olive oil from €4.7-2.7 per kilogram to just €0.3-0.5 per kilogram, demonstrating that efficient production lowers food prices at the consumer level [3].

The Future of Agri-Tech

Automated robotic arms performing farming activities.

Mechanization and automation in agriculture address global issues like labor shortages, inflation, and climate change. Yet, some tough barriers exist to adopting these new technologies. As stated in a previous blog post (link to previous blog), farmers face barriers like high initial costs, lack of knowledge and training, infrastructure challenges, uncertain return on investment, and data and privacy concerns. While these challenges slow the adoption of rapidly advancing agri-tech, innovations in blockchain, AI, robotics, and smart farming systems offer solutions to these concerns. Storing data on the blockchain addresses data and privacy concerns by providing encrypted data management, reducing the risk of counterfeiting and data theft.

Monitoring factors like water usage, chemical usage, temperature and various other data on an interface is made possible using automated smart devices connected by an Internet of Things.

Precision agriculture allows farmers to make data-informed decisions about planting, fertilizing, and harvesting using IoT sensors, GPS, and AI. Drones, satellite imaging, and robotic harvesters can track crop health and predict harvest timing while alleviating labor shortages. Irrigation systems can be affixed with smart sensors and AI-based decision-making to ensure that water is delivered efficiently and accurately. Farming techniques like vertical farming and indoor agriculture use hydroponics, aeroponics, and AI-powered climate control to optimize land use and harvest yield [21].As more farmers seek to embrace these technological advancements to remain competitive, a pronounced focus on user experience makes way for intuitive end-user interfaces that require minimal training.

Bespoke Designs for Mechanical Harvesters

Thunderbird Plastic specializes in creating custom HDPE injection-moulded designs that are specifically tailored for mechanized harvesters.

Our agricultural product line.

Each of our products can be made in a custom color and branded with our client’s logo.By collaborating directly with farmers and equipment manufacturers, the engineers at Thunderbird Plastics can also customize bin sizes, shapes, and features to meet the requirements of various mechanized harvesting machines. A customized agricultural bin or tote that can withstand the rigors of agriculture will improve the overall workflow of the mechanized harvester. Our special focus on quality, function, and customization ensures the highest operational efficiency and customer satisfaction!

Call us at 888-77T-BIRD or email us at info@thunderbirdplastics.com TODAY!

References

1. Government of British Columbia. (2025, February 14). Farm mechanization. Retrieved from https://www2.gov.bc.ca/gov/content/industry/agriculture-seafood/business-market-development/structures-mechanization/farm-mechanization

2. ScienceDirect. (2025, February 15). Mechanical harvesting. Retrieved from https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/mechanical-harvesting#:~:text=There%20are%20different%20types%20of,air%20blasting%2C%20and%20robotic%20harvesting

3. Sperandio, G., Biocca, M., Fedrizzi, M., & Toscano, P. (2017). Economic and technical features of different levels of mechanization in olive harvesting. Chemical Engineering Transactions, 58, 853-858.

4. ȘERAN, P., Creț, C., Copcea, A. D., & Mihuț, C. (2019). Mechanization technology for wheat harvesting with self-propelled grain harvesting combine. Research Journal of Agricultural Science, 51(4), 2019.

5. Atlantic Project Cargo. (2025, February 17). Top 15 combine harvester producers. Retrieved from https://atlanticprojectcargo.com/insights/top-15-combine-harvester-producers

6. Ulyanov, M. V., Skripkin, D. V., Kharlashin, A. V., Ulyanova, A. V., Ayugin, N. P., & Khalimov, R. S. (2022). Improving the design of a root crop harvester in order to increase the sustainability of agriculture. IOP Conference Series: Earth and Environmental Science, 965(1), 012056.

7. FoodNavigator-USA. (2021, April 8). AppHarvest acquires Root AI and its game-changing robotic harvester. Retrieved from https://www.foodnavigator-usa.com/Article/2021/04/08/AppHarvest-acquires-Root-AI-and-its-game-changing-robotic-harvester

8. AgriExpo. (2025, February 24). Carrot harvester machine. Retrieved from https://www.agriexpo.online/agricultural-manufacturer/carrot-harvester-machine-1934.html

9. Tian, F., Xia, K., Wang, J., Song, Z., Yan, Y., Li, F., & Wang, F. (2021). Design and experiment of self-propelled straw forage crop harvester. Advances in Mechanical Engineering, 13(7), 16878140211024455.

10. AM Machinery. (2025, February 25). The 4 major brands of SPFH. Retrieved from https://www.ammachinery.nl/the-4-major-brands-spfh

11. El-Magd, A., Elbanna, E. B., & Ismail, Z. I. (2010). Development planting and harvesting sugar beet crop machine. Journal of Soil Sciences and Agricultural Engineering, 1(8), 895-919.

12. Ma, S., Karkee, M., Scharf, P. A., & Zhang, Q. (2014). Sugarcane harvester technology: A critical overview. Applied Engineering in Agriculture, 30(5), 727-739.

13. Microsoft News. (2025, February 26). Chasing peak sugar: India’s sugar cane farmers use AI to predict weather, fight pests, and optimize harvests. Retrieved from https://news.microsoft.com/source/asia/features/chasing-peak-sugar-indias-sugar-cane-farmers-use-ai-to-predict-weather-fight-pests-and-optimize-harvests

14. Wine Grape Growing. (2025, February 25). Mechanical wine grape harvesting. Retrieved from https://www.wine-grape-growing.com/wine_grape_growing/harvesting_wine_grapes/mechanical_wine_grape_harvesting.htm

15. Melnic, I., & Melnic, A. A. (n.d.). Current status in mechanized harvesting of nut crops. FRI-8.303 b-1-AMT&ASVM-07.

16. ScienceDirect. (2025, February 26). [Article]. Retrieved from https://www.sciencedirect.com/org/science/article/pii/S1874331519000171

17. Britannica. (2025, February 26). Cotton harvester. Retrieved from https://www.britannica.com/technology/cotton-harvester

18. Farm Progress. (2025, February 26). The future is autonomous. Retrieved from https://www.farmprogress.com/cotton/the-future-is-autonomous

19. Certipik. (2024). From field to fabric: Understanding cotton harvesting techniques. Retrieved from https://certipik.com/2024/05/from-field-to-fabric-understanding-cotton-harvesting-techniques/#:~:text=Improving%20Cotton%20Harvesting%20Techniques,while%20minimizing%20their%20environmental%20impact

20. How to Robot. (2025, February 26). Harvesting robots. Retrieved from https://howtorobot.com/expert-insight/harvesting-robots#:~:text=Harvesting%20robots%20are%20designed%20to,best%20gripper%20for%20the%20application

21. Eden Green. (2025, February 26). What is vertical farming?. Retrieved from https://www.edengreen.com/blog-collection/what-is-vertical-farming

22. Sed Graders. (n.d.). Automation: Helping Oyster Farmers. Retrieved from https://sedgraders.com/automation-helping-oyster-farmers/

23. National Marine Fisheries Service. (n.d.). Fisheries of the United States, MFR 1094. Retrieved from https://spo.nmfs.noaa.gov/sites/default/files/pdf-content/mfr1094.pdf

24. YouTube. (2025, March 5). Oregon Seaweed Farming Revolution: A Unique Dulse Seaweed Aquaculture Farm Tour. Retrieved from https://www.youtube.com/watch?v=E8c0GqOzCIY

25. Hicks, J. (2021, July 28). Here is a fully autonomous AI-powered beehive that could save bee colonies. Forbes. https://www.forbes.com/sites/jenniferhicks/2021/07/28/here-is-a-fully-autonomous-ai-powered-beehive-that-could-save-bee-colonies/